HPL Exterior Wall Cladding Panels: Merging Beauty and Performance

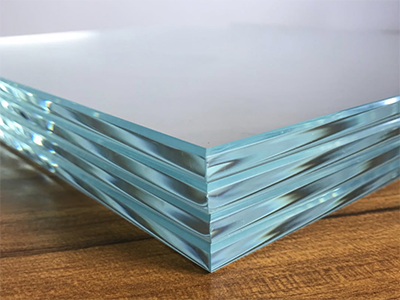

The exterior of a building is more than just a protective shell; it's a canvas for architectural expression. A well-designed exterior not only enhances a structure's aesthetics but also plays a vital role in protecting it from the elements. High-Pressure Laminate (HPL) exterior wall cladding panels have emerged as a dynamic solution that combines beauty and performance to create visually stunning and durable facades. In this article, we'll delve into the world of HPL exterior wall cladding panels, exploring their attributes, benefits, and their impact on modern architecture. Unveiling HPL Exterior Wall Cladding Panels What Are HPL Exterior Wall Cladding Panels? HPL exterior wall cladding panels are composite panels constructed from multiple layers of kraft paper impregnated with thermosetting resins and fused together under high pressure and temperature. The outer layer is adorned with a decorative paper that can mimic various textures, patterns, and even natural materials ...